Our Stories

On February 2, 2017, Irving Shipbuilding spoke to the House of Commons Standing Committee on National Defence about the importance of the National Shipbuilding Strategy.

James D. Irving, Co-CEO, J.D. Irving, Limited

Good afternoon, Mr. Chair, and members of the committee. Thank you for the opportunity to speak to you today and to provide an update on our work at the Halifax Shipyard.

With me today are members of the executive team at Irving Shipbuilding – Mr. Ross Langley, Vice Chairman, Mr. Kevin McCoy, President, and Mr. Scott Jamieson, Vice President of Programs.

We have a proud history of building ships for Canada. We’ve built more than 80% of Canada’s current fleet and the Halifax Shipyard has been maintaining the Royal Canadian Navy’s fleet since its inception.

Canada can be proud of the National Shipbuilding Strategy. After a long period without building large ships in Canada, we now have a strategy that makes sense for Canada and Canadians and will make sure the Navy and the Coast Guard get the ships they need at a fair price.

We have gone around the world to bring in the best management team with the right experience to lead our Canadian workforce to becoming world class performers in the industry.

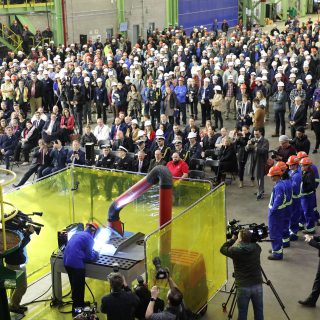

We invested over $360 million dollars to construct state-of-the-art facilities with the best equipment for the efficient building of Canada’s naval ships. We are committed to not only doing a great job building ships for Canada, but also making sure that the industry remains sustainable for the long term.

Finally, we are spending a lot of effort to tell the story of our progress and success to Canadians through our website and other communication means. Every time there is a contract placed or a Value Proposition announcement we get the word out so Canadians and government leaders have a chance to see the good things happening as a result of the Shipbuilding Strategy.

We are proud to continue our long history as a trusted partner in Canadian shipbuilding.

Kevin McCoy, President at Irving Shipbuilding, will speak to the work underway at our Halifax Shipyard and the benefits across Canada.

Mr. Kevin McCoy, President, Irving Shipbuilding

Thank you Mr. Chair and committee members for having us here today.

I joined Irving Shipbuilding in 2013, after a long career in the shipbuilding industry, including 36 years in the U.S. Navy.

I was honoured to be appointed President of Irving Shipbuilding at a time when the shipbuilding industry in Canada was changing significantly as a result of the National Shipbuilding Strategy.

The National Shipbuilding Strategy was first conceived by Canada due to a lack of sustainability in the marine and shipbuilding industry nationwide.

This boom and bust cycle of the industry was experienced at all major shipyards and the communities those shipyards reside. It resulted in an inability to stay up-to-date with modern shipbuilding practices, and created challenges in recruiting the best shipbuilders.

In developing the framework for the Strategy, Canada acknowledged that there was not enough large ship construction required for the Navy and Coast Guard to sustain more than two shipyards and their skilled workforce for the future.

It was through a fully transparent and competitive process that Irving Shipbuilding was selected as the Centre of Excellence to build Canada’s future combat fleet.

Today, we are well on the way to re-establishing the capability to build large ships in Canada and we are making excellent progress toward providing the Navy with the ships they need to operate as a true blue-water maritime force.

Currently, our shipbuilders are hard at work building Canada’s first two Arctic and Offshore Patrol Ships or AOPS. We expect to deliver the first AOPS, the future HMCS Harry DeWolf at the end of 2018.

The work we are doing now on AOPS will afford our workforce the experience and expertise required to construct Canada’s next combat fleet, the Canadian Surface Combatants or CSC, starting in the early 2020s.

We are working closely with Canada to ensure the right foundations for this program, including the appropriate ship requirements, budget and schedule.

As the prime contractor, we look forward to awarding a contract to start working with the CSC ship and combat systems designer in fall of this year.

It is imperative that we work at a steady pace and minimize delays. There are several pressing reasons for this:

First and foremost, the Navy needs the capability that these ships bring to the fleet. Canada’s only three destroyers, which were to be replaced by CSC, have already been removed from active service.

Second, starting in Fall 2019, production work on AOPS starts to wind down. If we don’t put our skilled shipbuilders to work on CSC we face significant layoffs. If there is a production gap between the two shipbuilding programs, the cost to reconstitute this workforce and their experience will be borne by the CSC Program.

And third, the impact of inflation is very real on a shipbuilding program such as CSC. With shipbuilding inflation running 3-5 percent annually, on a 15 ship program you lose the buying power equivalent of 45-75 percent of one ship for every year of delay. Delays have a serious impact on a program such as CSC.

Let me shift to economic benefits and the impact our work is already having across Canada.

The benefits span far beyond the walls of the Halifax Shipyard, where our headcount has surpassed 1,400 and is growing. With the CSC Program, we expect to reach over 2,500 employees.

As of December 31, 2016, we’ve issued purchase orders totaling more than $1.2 billion dollars to over 250 companies across Canada.

According to Conference Board of Canada analysis this will support an estimated 16,560 fulltime equivalent person years of employment, and generate an estimated $895 million in income, $385 million in taxes and $620 million in consumer spending.

These are real benefits for Canadians from coast to coast to coast.

In Ontario, where over $543 million in contracts has been awarded, we have a 7-year contract with GE Canada for electrical power, propulsion systems, installation and commissioning services for six AOPS vessels.

In Quebec, where over $61 million in contracts has been awarded, we have the pleasure of working with Bronswerk Group, who is supplying heating, ventilation and air conditioning solutions for AOPS.

Bronswerk’s AOPS contract has allowed the company to grow by 25%, open two facilities in Halifax, and be able to compete for other global contracts.

In addition to our direct contracts, there is work happening throughout Canada that may seem unrelated to the construction of navy ships, yet would not exist without the National Shipbuilding Strategy.

For example, Aspin Kemp & Associates in Montague, PEI was awarded an initial $80M contract with GE’s Global Offshore and Marine division to provide electrical components for drilling ships. This was a direct result of GE’s Industrial Regional Benefits (IRB) obligation under their contract with Irving Shipbuilding to provide AOPS propulsion equipment. The spin-off work for drilling ships awarded to Aspin Kemp, which GE was previously having done internationally, is now valued at more than $160M and has created new jobs and millions of dollars of economic growth on PEI.

These are just some examples of the hundreds of companies across the country – from Toolcom, an aboriginal owned company in BC providing Communications Systems (UHF/VHF Radios) and Internet Protocol, to Glamox, a lighting supplier located in a former fishing plant in Newfoundland and Labrador – that we are proud to be working with to create a sustainable shipbuilding industry.

We have also invested in training and education programs to develop 21st century shipbuilders and modernize the face of shipbuilding.

Two programs we are very proud of, Women Unlimited, with 17 female students, and Pathways to Shipbuilding, with 19 indigenous students, are the first of many designed to provide training and employment opportunities at Irving Shipbuilding to underrepresented groups.

These are Canadians who now look forward to a bright future with a long term, stable career in the trades with salary of over $70,000 per year plus benefits.

While we are hard at work on the Canadian Navy’s future combat fleet, we need to also keep in mind how we are maintaining our current fleet.

In November, we were pleased to complete the refit portion of the Halifax-Class Modernization project on-time and under budget. This involved extensive work on all seven of the East Coast Frigates to modernize the ships and their combat systems.

This project not only sustained over 400 jobs in Halifax for the past six years, but once again provided the Navy with equipment required to successfully serve at home and abroad.

The success of this project can largely be attributed to the close proximity of our facilities to the Navy’s east coast homeport. The same is true for Seaspan on the West Coast. During this program, the shipbuilders at both Irving Shipbuilding and Seaspan honed their skills and truly developed into Canada’s Centers of Excellence for maintenance and modernization, in addition to shipbuilding.

We are very concerned that Canada’s current approach to running individual procurement competitions for ship maintenance is not in Canada’s or the RCN’s best interest, and strongly recommend that Canada take a holistic strategy with regard to ship construction and maintenance. Let me explain:

First, the real cost to Canada— During the Halifax-Class Modernization project, the cost of shipbuilding at the Halifax Shipyard was decreased, as a significant portion of our fixed overhead was spread across both new ship construction and maintenance. In 2016 alone, this resulted in a lowered cost of over $20M on AOPS – this is equal to getting roughly 130 shipbuilders per day for free.

Second, sustaining the shipbuilding workforce – Both new construction and maintenance work go through peaks and valleys of demand for individual trades. Critical to eliminating the boom-and-bust cycle for employees and the industry is having both new construction and maintenance work in the shipyard at the same time. As Canada’s shipyards have clearly experienced over the last 20 years, ship maintenance alone is not sufficient to eliminate the boom-and-bust periods.

Third, the impact on ship readiness and crew morale—Canada’s current strategy could result in the Halifax-class Frigates and crews leaving homeport in Halifax for maintenance elsewhere. This would result in undue stress on crews and their families; increased costs for the Navy and Canada; and the need for another shipyard to familiarize themselves with the ships and procedures that Irving Shipbuilding is now an expert. I will also point out that Halifax is an ice-free port year-round allowing ships to be maintained and deployed at a moment’s notice.

And finally, leveraging long-term investment—The current strategy of spreading out maintenance to many shipyards around the country does not leverage the significant investment in people, facilities, and processes that come with a sustained shipbuilding program. Investment in these areas requires the long-term certainty.

Canada’s allies in both the United Kingdom and the United States actively manage maintenance and in-service support as part of their overall strategy for shipbuilding, enabling a steady workforce year-round, and leveraging investments in facilities for both construction and support. We strongly encourage Canada to take a similar approach.

In closing, we are proud to continue our long history as Canada’s shipbuilder and create a legacy for the Navy and Canada through the National Shipbuilding Strategy.

The Halifax Shipyard and employees take that responsibility very seriously, and we look forward to a bright and productive future that will benefit not only men and women in uniform, but all Canadians.

Thank you again. We are happy to take your questions.